A new take on acoustic design

Acoustics matter, whether you’re in an office, a restaurant or at home. Sound reflections and reverberations can interfere with conversation, break our concentration and ruin our cinematic viewing pleasure. Noise absorption helps avoid this, and to this end, Koest designed modular acoustic wall panels that boasts the highest level of sound absorption in a striking yet timeless design.

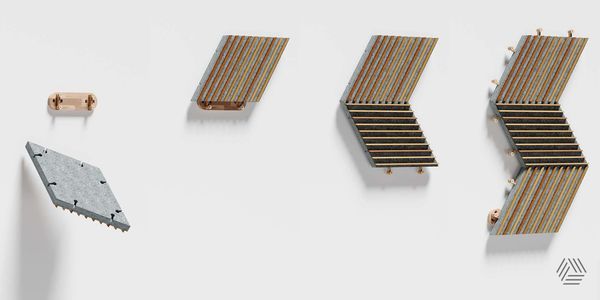

Its panels can be configured in a variety of ways, allowing you to create a distinctive wall feature that is as delightful for the eye as it is kind to the ear. And if more absorption is needed, simply add more acoustic panels. The panels are made from sustainable materials and produced in a socially responsible manner.

The highest level of sound absorption

The acoustic panels are made of PET felt and wood, a unique combination. The felt is 40 mm thick, providing the highest level of sound absorption possible. The wood is attached to the felt by dovetail projections and provides acoustic diffusion, i.e., it spreads sound energy evenly across the room. The panel hangs two centimetres from the wall, thereby providing additional sound absorption. The combined effect is an absorption coefficient of up to 1.1a, depending on sound frequency (Hz).

Sustainable and socially responsible

Koest are avid fans of stylish design, high standards and socially responsible manufacturing. Thus, the acoustic wall panels are made from sustainable materials sourced as locally as possible. The felt comes from Germany and consists of 60% recycled PET bottles, and is 100% recyclable. The wood comes from the residual waste of industrial activity in the Netherlands — mainly leftover lumber, scrap wood and discarded wood packaging material, which we give a third life as sound diffusers — and is thus also 100% sustainable. Bamboo plywood is used for the wall mounting and connecting elements of the panels. We cut the felt in Limburg and process the wood ourselves. The panels are assembled, packed and shipped from a sheltered employment workplace in Nijmegen.

The wooden elements of the acoustic panels are produced by means of traditional woodworking craftsmanship, while the PET material is cut into shape with precision CNC machinery. The two materials are joined by dovetail projections that fit into corresponding slots, thereby requiring no adhesives. This not only avoids the need for tools in separating the materials if necessary, but also facilitates later disassembly and repurposing.

Who are Koest?

We, Joost Lindner, Joep Grootings and Jeroen Bomers founded Koest on the belief that there should be a solution for terrible acoustics in everyday environments. As an inventor, designer and creative marketeer we searched for one that was both aesthetically pleasing and sustainable. Eventually we found it in the right combination of felt and wood. Our mission is to innovate the world of acoustic materials for everyday environments in a responsible way.

Contact

Acoustic panels

Our entire operation is as circular as they come, defined not by empty words and false marketing claims about sustainability, but by a deep commitment to environmental and social responsibility. Read our full story to find out more.

Koest Acoustic Design B.V.

Gruitberg 22, 6511 KV Nijmegen, Netherlands

VAT: NL 863 259 881 B01 | KVK: 84561254

Copyright © 2023 Koest Acoustic Design - All rights reserved